SICK Robot Day 2014

delivery of wooden cubes

This year autonomous robots were delivering wooden cubes (a printed barcode defined the target location). Up to four robots were competing at the same time. There were 15 teams competing. How it went? See the compilation of the best teams … Update: 21/10 — Photos (Standa)

This article is a compilation of contributions from several participating

teams. The content may evolve with the time, as new texts will arrive or some

parts will be translated cs<->en. Please note, that currently the Czech and

English version are very different! The Czech version

(Google

translation … it looks like Google is giving up in the middle) primarily

contains blog about Eduro Team preparation, so it is much longer.

Content

- 1st place: PARMA (6 points (+5))

- 2nd place: Attempto (6 points (+3))

- 3rd place: Deep Cube Osnabrück (3 points)

- 4th place: Eduro (2 points)

- 5th place: eXception München (1 point)

- Photos

Note, that all other teams did not finish with a positive score.

1st place: PARMA Team, Parma

PARMA (Personal Autonomous Robot for Mobile Applications) Team

International competition for mobile robot. The challenge is organized by SICK AG and RIMLab took part in

2010 and

2012, and won the latter. This year

robotic race is a kind of mailman race. The arena is a convex bullpen of about

13 x 13 meters, which contains an "island" in the middle with the filling

stations. At each round four robots receive a wooden cube with a bar code from

a filling station. The bar code gives the number of the goal stations to reach.

The more goal stations are correctly visited in the given time (10 minutes),

the higher is the team score. Of course, the robots must avoid collision with

other robots and the border of the arena. For more information see

Robot

Day general rule. The event took place on Saturday October 11th 2014 in the

Stadthalle in Waldkirch (Germany). PARMA (Personal Autonomous Robot for

Mobile Applications) from the University of Parma won the competition

delivering 5 cubes in the first run and 6 cubes in the second one.

First Run

Second Run

Robot Hardware: Actuators and Sensors

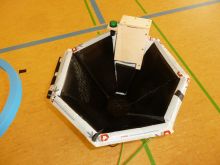

The robot is a

MobileRobots

Pioneer 3DX

provided with a basket to carry the wooden cubes as required by

the competition. The basket has the shape of a funnel to bring the cubes to

its center.

The basket contains two kinds of sensors to read the barcodes placed on the

faces of the cubes: a

Sick

ICR803-B and two

Logitech C270 USB

cameras. Sensor ICR803 is positioned to keep the proper distance from the

center of the cube (about 10 cm). The USB cameras provide a redundant cube

detection system based on a computer vision library to read barcodes

(zbar library). A LED is placed inside the

basket to light up the cube and a green one to signal that the robot is ready

to receive or deliver. The LEDs and the interface with Sick ICR803-B are

controlled by an Arduino One board.

The robot is also equipped with a

Sick

LMS100 laser scanner and a

Point Grey

Bumblebee XB3 part of Vislab

3DV Stereo Vision. The LMS100 laser scanner is the reliable and robust

sensor that allows obstacle detection and navigation. The 3DV stereo vision

system provides the left and right images, the disparity map and the 3D point

cloud obtained by stereo processing. Unfortunately, there was not enough time

to develop algorithms for 3D processing (e.g. to estimate the 3D poses of

numbered plates).

Computer Vision Perception

The computer vision is used to detect numbered plates and targets. Number

plates are the labels of goal stations. The targets are placed in front of

each filling and goal station. Like for many computer vision methods, the

developed algorithm initially search the regions of interest (ROI) and, then,

performs classification and tracking. First, the ROIs are found by extracting

lines (using EDLines algorithm) and rectangles from each frame. Second, in the

case of plates, the content of the ROI is classified by a trained Artificial

Neural Network (ANN) according to the OCR histogram of the rectified ROI. In

the case of targets, the detector searches circles, lines and their

intersection points.

The pose of plates and targets is estimated using the projective geometry and

the information on their size. Furthermore, the estimated poses (i.e. the

projection in the scan plane) are validated by the laser scanner. A pose is

valid only if its projection corresponds to an obstacle.

Navigation

The navigation module manages the mission state, the path planning and the robot motion.

It consists of several subtasks.

- Local Planner. The local planner builds a local occupancy grid map using the measurements from the laser scanner and inflates the obstacles. Given the goal pose (e.g. a pose in front of a numbered plate or of a filling station), the planner computes a trajectory on the occupancy grid map according to a graph search algorithm (tested algorithms: Generalized Voronoi Disgram, A*, D*).

- SLAM Module. The SLAM module builds a map of the environment consisting of the robot poses and of the numbered plates used as landmarks, and iteratively updates the estimation of robot pose w.r.t. the initial reference frame. The odometry and vision measurements are integrated into the Graph SLAM framework g2o. This modules provides the goals (the filling and goal stations) to the planner.

- Approach Task. The approach module allows the robot to reach its goal (a filling or goal station) aligned with the arena fence. It exploits the observation of the targets in the image.

The following video illustrates how the modules work together with a simulation

(the simulator is Gazebo, integrated in ROS).

PARMA team, winner of Sick Robot Day 2014!

Front from left to right: Fabrizio Castelli (Sick Italia), Fracesco Valenti,

Marco Pedretti, Marco Paini. Back from left ro right: Cecilia Bollati (Sick

Italia), Marco Allodi, Fabjan

Kallasi, Domenico Giaquinto,

Dario Lodi Rizzini.

Questions & Answers

Where there any failures of your robot during competition?

The main failures we observed are related to the recognition of filling station

state. Actually, the robot checked whether the filling station is occupied by

another robot by assuming that the filling station fence appear like a segment

when observed by the laser scanner. Furthermore, such segment must lie close to

the expected position of the filling station (from the map). In the end of

second run, it seems that free filling station detection is difficult. We

suppose that two things can have influenced such behavior.

1) We expected a square island in the middle of the arena (the rule of

procedure is somehow ambiguous: They are located at the 4 sides of a square

island

(en-rules)

and instead it was octagonal. Of course, we adapted thresholds, but the initial

assumption has an impact on the algorithm design.

2) The pose of filling stations is not updated by the mapping module, but it is

initially set. The map contains only robot and numbered plates poses (with the

constraints given by odometry measurements). Hence, an error in robot pose

estimation (that, in spite of SLAM, increases a bit) can affect the decision on

busy/free state.

Any other surprises?

Another surprise was the limited number of goal stations: only 4, we expected

8. This low number increased traffic and competition for stations. This was a

problem at least in our first run.

How did you detect the navigation target?

There are slightly different algorithms to detect numbered plates and targets.

- Numbered plates: detection relies on rectangle detection and, then, the inside is classified by a trained ANN on histogram.

- Targets: detection exploits circle detection (at different scales, to make it more robust).

The pose of the two target is estimated through perspective geometry

(mono-camera estimation, not stereo!) since the size of the two items is known

(see solvePnP() in OpenCV). In both cases, the laser validation is required.

The numbered plates are detected by vision also from 12 m if no occlusion

occurs, but since laser validation is required to accept it the full detection

occurs when the robot is closer to the plate. Of course, the estimation only

with vision is noisy in particular for the orientation of the plates (the yaw

angle changed also of 20 deg between two observations!). Thus, a proper

tracking was added.

We had a problem (never observed in our month-long trials in Parma!) during the

trials in the morning. One of the windows with a sloopy roof was similar to

plate with number 4 and its size was compatible with the distance of the

filling station fence. We added a constrain: to be accepted a number must lie

on the external fence. This solved the problem and, then, they closed the

curtains in the afternoon.

2nd place: Attempto Tübingen

This year we were able to continue our successful participation at the SICK

robot day, placing second out of 14 teams from Germany, the Czech Republic,

England and Italy. The competition was again organized by SICK AG in Waldkirch

near Freiburg, Germany.

The task

This year's task was to collect cubes at a collection station at the center of

a circular arena. These cubes were labeled with barcodes, which represented

one of four delivery stations at the outer border. These deliveries were

marked with the same signs already in use back in 2010. The robot got one

point for every correctly delivered cube, and one negative point for each wrong

delivery.

Our robot was able to deliver 6 cubes in 10 minutes in the first round, just as

many as the winning team PARMA delivered in their better run. In the second

run we had a hardware problem, leading to a 5 minute pause in which our robot

did not move at all. Afterwards the robot was able to collect a few cubes, but

not enough to achieve the first place.

Our approach

Our robots Arnie and Sly are based on a former, omnidirectional RoboCup

robot that has attended the SICK robot day twice in the past. They were heavily

revised in order to meet the requirements for the tasks of this year's event.

The most important revision was to make the robots as low as possible to be

able to drive under the pick up and delivery rings.

A combination of multiple methods was implemented to solve the sign and target

detection problem. These includes artificial neuronal network based machine

learning methods as well as Hough line detection. Furthermore we implemented a

RANSAC based map analysis to detect the central area, which was supposed to be

square, but ended up being an octagon.

We used a customized version of slam_karto

for localization and mapping, which was optimized for faster grid map

generation. Furthermore we employed laser scan segmenation to only map long

segments for a more robust system. Path planning was done using A* with an

omnidirectional motion model and path following was implemented using

orthogonal projection and an exponential law.

Team Attempto

Attempto Tübingen is a team of students and faculty staff with background in

Computer Science, Bioinformatics, Automation, Control and Cognitive Science.

Our two robots Arnie and Sly are based on former RoboCup models that have

attended SICK Robot Day twice.

Team Members

- Sebastian Buck (sebastian.buck at uni-tuebingen.de)

- Richard Hanten (richard.hanten at uni-tuebingen.de)

- Goran Huskić (goran.huskic at uni-tuebingen.de)

- Alina Kloss

- Jan Leininger

- Gerald Rauscher (gerald.rauscher at uni-tuebingen.de)

- Eugen Ruff

- Felix Widmaier

More information

Questions & Answers

Failures?

- Waiting times were too long. We waited the full 10 seconds at delivery and pick up stations. We had to wait for ~6 seconds every time we were approaching a target sign.

- In the second run we had a spurious measurement of our main laser scanner which reported an obstacle directly in front of our robot, which caused a 5 minute long pause.

Surprises?

- The rules stated that the central area was square, so we used this knowledge to find the four pick-up stations. On site we had to rewrite this central part of our system to detect an octagon instead of a square and to decide, which four sides of the octagon were equipped with a station and which not.

How did you detect navigation targets (Zielscheibe)?

First we projected the front laser scan onto the image to mask out everything

but the border plane in which the targets where positionend. Further masking

was performed using morphological gradients to detect regions of interest.

Then we performed Canny line detection and the Hough Transform on these ROIs to

find vertical and horizontal lines and looked for the crossing point, the

circles / ellipses were totally ignored. We then used the camera calibration

matrices in combination with the projected laser scan to determine the pose of

the target. The poses were averaged over a few measurements, which was not

that efficient (especially on our Core2Duo CPU) and caused the waiting

pauses.

4th place: Eduro Team, Praha

Robot Eduro participated on SICK Robot Day already in

2010 and

2012. This was an advantage, because we

already know how difficult the contest is and we had some idea what troubles we

can expect .

Robot

Eduro is already proven prototype platform with proprietary SMAC (Stepper Motor

— Adaptive Control) motors, CAN bus, a single board x86-based computer

running Linux OS (AMD Geode CPU/500MHz, 256 MB RAM, compact flash card, Wi-Fi,

3 Ethernet, 1 RS232 and 2 USB ports) and it is powered by two 12V/8Ah sealed

lead acid batteries.

Eduro is equipped with CCTV IP camera with with fish-eye lens. Since 2010 it

has also laser scanner LMS100, thanks to SICK. You can find more about the

platform in the

Robotour 2010

proceedings.

There was an extra bar code reader attached to USB port for this contest.

Software

The software is written mostly in Python and some parts, like image processing,

are written in C/C++ (using OpenCV library). The source code is freely available at:

Version 0

I think that concept of „version 0” can be dated back to

Eurobot contest where robots had to pass

homologation i.e. score at least one point without opponent robot. It is

the simplest thing that could possibly work, i.e.

eXtreme programming in

robotics. If you have ver0 you can relax a little bit — you have something

working. You can also start to collect data and see what bits

are the real problem and where improvement is needed. And if everything goes wrong you still

have something to compete with .

For SICK Robot Day 2014 this meant delivery of one cube. Well, 24 hours

before the contest we did not have tested algorithm what could be called version

0…

Target recognition

The main difference (when compared to 2010 contest) were navigation targets and missing columns with numbers.

This algorithm was critical because without that

Eduro failed to collect a cube.

The recognition of numbers (see bellow) is based on contours extracted from

thresholded image. It was necessary to use the same concept to reduce

computational requirements.

The idea was to look for a contour containing twelve smaller contours. Because

black lines are relatively thin it was necessary to erode image by 3x3 kernel

(see Python version

recognizeNavTarget()

for details).

We had to add some constrains for these 12 small contours to limit the number

of false detections. There were surprises like for example the area of the

bigger arc does not have to be bigger then area of inner arcs (it should be

mathematically but sometimes it fails in reality). Minimal bounding

rectangles were used instead and „area” was then estimated from their size.

And that worked fine.

The rejection rule was that 4 biggest sub-contours have to be in the four

corners and then next 4 biggest sub-contours have to be again in all four

corners. This was even fun to watch: see

video — frames with detected

target are 10 times slower and once a while you can see „random colors” which

are 1+12 contours groups failing to fulfill the criteria.

Digits recognition

The recognition of digits did not work very well in 2010 — in particular I still see

the image of rObOt day poster where two letters 'O' were connected and Eduro

classified that as digit '8'. The old algorithm expected first to detect the

frame and then only decided what is the content, but … there were really

bad light conditions in 2010 and plate frames just „disappeared”.

The 2014 code was very similar to the one in 2010. Note, that there was also an

experimental solution on parallel RaspberryPi which I refused to integrate at

the very end as „not sufficiently tested”. On the way to Germany (approx. 12

hours drive due to many traffic jams) this code was revised so that it could

work even without the frames. We needed high reliability of detection so we limited

the size of numbers to really big, the height and position in the image had to

be in given proportions, and we re-introduced frame detection. Image erosion

needed by target recognition also helped with frame detection.

Results

The contest for us was really the fight for the 3rd place (and the winners of

2010 and 2012 would split the first and second place). Eduro expected stright

wall near the navigation target, and that sometimes failed for used octagon.

Because Eduro is not omni-directional robot, and image frames were approx. at

1Hz with 1s delay the idea was to get 40cm from the wall with laser feedback

and turn towards the target (processed camera). Eduro has very precise odometry

so it is capable to turn by desired angle and backup.

While during the tests at home we sometimes had problem detect target even at

50cm in Waldkirch it worked from 2 meters! Pickup worked in 4 of 4 attempts, but

the problems were near the goal.

The first problem was that there was an obsolete code using angles instead of

absolute position for approaching numbers from close distance.

The second major problem was missing verification if robot is heading towards

island or border causing infinite shaking in order to recognize non existing

cube.

Thanks to „blocking rule” we were allowed to restart Eduro and collect two

cubes in each run. In the second run we re-entered the same feeder and got

minus point for that. In total we finished on shared 4th place which I would

still consider a success .

Questions & Answers

How did you solve the non-square center problem?

Well, we did not. The pickup of the first cube was without any problem and for the next

cubes we tried to navigate to the center of the „occupied area in the

middle”. There was a backup to go around the island if the target was not

recognized and that would work for both octagonal as well as square.

Verification that nearest reading is from perpendicular obstacle was not added at the

end.

Photo (Stanislav Petrásek)

eXception, KaMaRo, R-Racing, Deep Cube, Hector, BARC, Flamingos, MART, Parma, Idefix, Gymspit, 01-robotics, Attempto, Alpaca/2 |

If you have any question or comment (including questions to presented teams) —

contact us.