Barbora

tracked vehicle with color camera and PC onboard, 2002

Barbora was designed primarily to participate in the Eurobot 2002 competition. Another even more important motivation to build the robot was the desire to build an universal bogie to be used in the following competitions and to have a reliable platform for further research and experiments. Unfortunately we have not finished the robot in time to qualify to the competition. However it has shown to be an excellent drive while building the robot and it has certainly helped us to achieve what we have.

Quick Facts

The robot is built around a PC-like motherboard

running a customised version of the Linux kernel. Two brushless DC motors

provide the power to move and 4 optical USB mice the required odometry feedback.

Additional sensors include onboard and offboard (wireless) CMOS cameras and

optical reflective infra red sensors to detect the color of the floor bellow the robot.

Unique helix storage system is the base for ball manipulation.

The software side includes

MCL (Monte Carlo Localization)

position tracking,

RRTs (Rapidly-Exploring Random Trees) path

planner and fast image analysis based on color tresholding.

Boggie

The boggie is built from the off-the-shelf components for the

most part, namely ones used for the aircraft and automobile models, as well as

some used in the process automation. The usage of the off-the-shelf components

was motivated by overall lower production costs of the robot, as well as by the

decrease of the developement time. Having done the preliminary design of the

boggie construction and functional parts, the manufacturing details were tuned

up by the company Vakuum Praha,

a company collaborating closely with the

Faculty of Mathematics and Physics,

Charles University in Prague where most of

the team members come from. Vakuum Praha specializes in vacuum science and and

precise machinery and has machined the boggie for us.

The boggie is made of aluminium to be light and durable. Viewed from above

the platform is roughly a squared, 30x30 centimeters (12 by 12 inches). The

height of the boggie containing motors and bateries is around 6 centimeters

(2.36 inches).

Locomotion of the robot is provided by two brushless DC motors

with neodymium cores produced by a Czech company

Mega Motor. These motors are

lightweight (160 grams, 0.4 pounds) and provide excellent mechanic power —

more than 600W each, giving the robot 1.2 kWatt (1.6 horsepower)

peak thrust,

resulting in peak acceleration of 20ms-2 (2G). The maximum speed of the

boggie is 4ms-1 (9 mph). The robot should be able to reach the maximum

speed in less than a quarter of a second (expecting perfect adhesion, no

sliping). To achieve good stability (even in high speeds and obscure manoeuvres)

and high traction the boggie is equipped with tracks made from industry standard

HTD synchronous belt. Similar belts are used for a gearbox between the motors

and the tracks because we have not been able find a more suitable gearbox

fulfilling such a high requirements such as the ability to handle the power and

high rpms and size small enough to fit inside the boggie.

The drawback of the motors is that they require a quite complex electronics

to drive. Since they have no mechanical commutator they require three phase

power with variable frequency at low voltage (12 Volt) and high current (50

Amperes peak). On the other hand due to the the lack of mechanical commutator

the motors offer unprecedented reliability and very high power/weight and

power/size ratios.

Fortunately the

TMM 40e-3ph motor

controller produced by a Czech company MGM-Compro

is exactly what we needed and with some necessary modifications to

its software (kindly made on our request by the manufacturer) are easy to use

with our main computer. The modifications consisted mainly from adding the

serial line communication instead of the regular PWM control signal used for

radio controlled models.

As a power source 20 NiCd cells are used, with aggregate voltage of 12V, and

capacity of 3400mAh. This allows the robot to run for 2 minutes (a match in the

Eurobot 2002 competition lasts 90 seconds)

at maximum power consumption. Because

the real power consumption is approximately ten times less, this is more than

enough (for the competition). However the test runs usually lasted much longer

and the drawback of the construction was that the bateries had to be recharged

while mounted on the robot. That forbided simultaneous testing and recharging

which in turn has made the testing unconfortable and less effective. For further

usage the batteries has to be made replacable to remove this limitation.

Ball Manipulation

A double copper helix is the base of the ball manipulation system. The helix can

store up to 7 balls inside the body of the robot. This allows the robot to

collect as many balls as possible and to distribute them in to the appropriate

baskets later on. The system is mounted on the top of the boggie in order to be

easily replaceable by other manipulation devices for future competitions and/or

research.

The balls are first collected by the opened part of the U shaped boggie. When in

the front part the ball is lifted by a pair of little manipulation arms. These

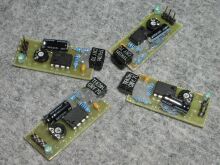

arms are powered by regular servo motors and driven by custom board based on the 555

chip. The board is connected to the LPT port of the mainboard.

The arms were the single most troublesome part of our robot. We expected them

to be an easy fix and that's why we have postponed theirs fabrication having more

important things to build. However it has proved to be a real headache, not working

all the time.

When lifted 8 cm above the floor the ball is taken by the helix storage

system. The helix itself stays fixed and the movement of the balls up or down

is achieved using a rotating cylinder in the center of the helix. The cylinder

is made of an aluminum pipe with a DC motor and two planet gearboxes inside.

The cylinder is fastened to the boggie with a smaller pipe coming out of it in

the center. The stator of the motor inside is attached to this pipe. The output

of the double gearbox (and in turn the rotor of the motor) is attached to the

outer housing made of the larger pipe. The overall effect is a cylinder with two

wires coming out of it with a rotating outer housing when power is applied to

the wires.

Electronics

The main controll unit of the robot is a single board computer

manufactured by Advantech,

PCM-5864,

20×12 cm (8×5 in), equipped

with an AMD

K6®-2 processor running at 500 MHz, 128 MB of RAM, audio

and video inputs, a 100MBit ethernet connection and an USB bus.

The motor controllers return the distance traveled. This information can be in

principle used to calculate odometry. However, treaded vehicles suffer from the

fact that the very principle of their operation is skidding and sliding offering

very poor odometry data. To supplement the information about relative movement four USB

IntelliMouse Explorer optical mice were used, offering resolution of

400 dpi and maximum tracking speed of 1.5 ms-1, by scanning the underlying

surface at a refresh rate of 6000 frames per second. As optical sensors don't

skid or slide over the surface, the robot can do manoeuvres (ie. controlled

skiding and sliding) which classic odometry navigation using IRC (Incremental

Rotating Counter) is not able to cope with gracefully.

The mouse based sensors provide relative movement information only. Therefore,

the error of the estimated position on the playfield can grow out of bounds with

time. To avoid this, the robot has five Vishay

CNY-70

optical reflective infra red sensors to

detect the color of the floor underneath itself. In the competition the sensors

were used to detect a line grid drawn on the table. Using this data, the

cumulative effect of the relative position tracking can be eliminated using the MCL

(Monte Carlo Localization) scheme.

The power to the electronics is delivered by a switching power supply based on

Maxim MAX787 components. This gives the

computer relatively stable input

voltage, while the voltage of the batteries varies under the load.

In order to locate the balls on the playing field the robot is equipped with color

CMOS camera. The camera is connected to the main computer through a CVBS interface.

Since the main board has video input, the picture from the camera is immediately

available for processing. In addition to the onboard camera the robot can

receive TV signal through microwave connection from an offboard camera located

in the corner of the plaing filed (in a beacon).

Software Architecture

Since we use industrial PC we are able to use the Linux operating system.

Linux gives us us maximum freedom in customizing the kernel and drivers for

maximum performance of the robot. The robot control software is partially

implemented in kernel (realtime critical parts) and as userspace processes

(CPU intensive computation — image processing, navigation, path planning).

Kernel Drivers

Going with the description in a bottom up manner we start with the kernel

drivers. The kernel drivers are composed of modules: tmm.o, mailbox.o,

fifo.o, mice.o, ct69k.o, cvideo.o, serio.o, serport.o, elevator.o. Modules

mailbox.o and fifo.o implement our own interprocess communication primitives.

Both require special inode to be created and from the user perspective act like

a file, meaning that it can be opened and closed, data can be read from it or

written to it and process can wait for a data to arrive. What differentiates our

IPC from the ones already provided by the kernel is the transparent support of

one-to-many and many-to-many communications.

Mailbox is a storage for a single data structure. Typically one process

writes the structure and other n can read it. Once a process reads the

contents of a mailbox the mailbox appears to that process empty (ie. a process

cannot read the same value more than once). If the mailbox is opened as

blocking, next read will stop the reading process until new version of the data

is available (ie. until the producing process writes into the mailbox again).

Fifo implements a queue-like access. When opened for reading it is

initially empty. When opened for writing and no process has opened it for

reading yet, it acts like a black hole throwing away all data written to it. When

a process opens the fifo for reading it starts receiving all the data written

to the fifo after the opening.

Other kernel modules are responsible for the various hardware parts of the

robot. The userspace programms can communicate with the hardware through

mailboxes, fifos and special devices created by these modules.

The hardware includes the TMM 40e-3ph motor controllers (tmm.o),

the IntelliMouse Explorer optical mice (mice.o), the video input (ct69k.o, cvideo.o)

and the helix storage device (elevator.o) connected to parallel port.

Localization (position tracking)

A position information is calculated using the

MCL (Monte Carlo Localization) algorithm. Relative movement

information is obtained from the optical mice. Each pair of mice provides

information about the change in position and orientation. We have 4 mice because

the mice has proved to be very unreliable in our context. The mouse requires

precise alignment with the surface and very precise height above the surface

(this height is also quite small). Because the optical sensor uses magnifying

lenses to detect even small irregularities on the underlaying surface it has

short focus range. If the mouse is too high or too low it reports invalid data.

Also the white lines present on the Eurobot 2002 playing field gave the mice

real headache. Using 4 mice instead of the minimum 2 gave us the advantage of

receiving 6 times (each pair) supposedly the same information allowing us to

filter out some of the problems.

The information about the relative displacement and the change in

orientation was used in the MCL algorithm. The MCL approach applies

sample-based representation of the three-dimensional state space of the robot.

When the robot moves or senses, sampling / importance re-sampling is applied to

propagate the belief over time integrating relative displacement information

with other sensors supplying information that can be compared with a known map

thus reducing the otherwise unbound growth of the integration error.

Path Planning

Our path planning algorithm is an implementation of

RRTs (Rapidly-Exploring Random Trees). A

Rapidly-exploring Random Tree is a data structure and algorithm that is designed

to efficiently search in nonconvex high-dimensional spaces. RRTs are

constructed incrementally in a way that quickly reduces the expected distance of

a randomly-chosen point to the tree. RRTs are particularly suited for path

planning problems that involve obstacles and differential constraints

(nonholonomic or kinodynamic). RRTs can be considered as a technique for

generating open-loop trajectories for nonlinear systems with state constraints.

An RRT can be intuitively considered as a Monte-Carlo version of a Voronoi

diagram, and certain variations can also be considered as stochastic

fractals.

The path planning takes commands from the strategy module and outputs a path.

In addition it uses the information about the current location of the robot and

the current locations of the balls. Output of the planning algorithm is a path

specified as a sequence of waypoints. Each waypoint contains displacement

relative to the previous waypoint in the sequence, the expected translational and

rotational speed and the time when to reach it.

Driving

Input of the driving module (the so-called wheelman) is the path

generated by the path planner. The wheelman's role is then reduced to a linear

interpolation of the current translational and rotational speed from one

waypoint to the other. The speeds are set by a feedback control loop based on

the PID algorithm. The required feedback is supplied by filtering the data from

the 6 pairs of mice.

Image Processing

The heart of our image processing module is YUV threshold based classification.

The camera geometry is calibrated and the positions of the balls relative to the robot

are calculated based on the fixed position of the camera with respect to the

robot and the pixel coordinates of the respective color cluster.

Object Tracking

The purpose of the object tracking module is to filter the output of the image

processing module using some information about past positions of the reported

balls. A Monte Carlo algorithm similar to the one used for the localization has

been used for the object tracking. Since all the balls of the same color are

from the point of image processing indistinguishable a single distribution is

used for equally colored balls. However this algorithm was computationally

expensive and it's performace was not as good as expected. The conducted

experiments suggested that regular averaging over last couple of frames is less

computationally expensive and more reliable. According to the results a decision

has been made to abandon the Monte Carlo tracking in favor of the simple

averaging.

Strategy

The strategy planning module is based on the assumption that the robot is able to

perform certain elementary actions. The task of this module is to generate a sequence

of these actions in order to maximize the chance of winning a match in the Eurobot 2002

competition.

Our first approach was based on hand-coded winning strategy using a FSM

(finite state machine). The approach had two primary flaws as we have

discovered later on during the developement:

- the offline design of the optimal strategy (ie. before the match) appeared harder and harder during the developement to that extent that we all agreed that it is nearly impossible

- even if it was possible the robot would never have enough information (ie. complete) about the state of the match to act according to it

The second approach is based on discretization of the game state space.

For each state there is an evaluation function which returns the worst possible

score that could be reached. This score is based on the assumption that the robot

can choose a “best” basket and decides to “defend” it — stand in front of it

not allowing the oponent to take balls out of it and expecting that the oponent is

as good as possible and has collected all the other balls.

The worst score is used to determine if the execution of a selected action

can lead to a worse final score or if even after the execution of the action

it is possible to maintain the current worst score. The safety of the execution

is calculated for some constant time interval into the future.

The selection of the next action is based on two assumptions: the action is safe and

the action is a part of a sequence that leads to an improvement in current worst

score.

The elementary actions the robot was able to perform were to move to a point

[x,y,α] or to command some of the actuators onboard. The elementary

actions could be hand-combined to form compound actions. The planner then

can build the plan using the compound actions. For example to take a ball out of

the basket is a quite long sequence of movement and actuator commands that can

be reused many times. By using the compound actions to build the plan the plan

stays compact and relatively short (less branching). The fact that the compound

actions can be decomposed to the elementary actions allows uniform determination

of the level of the safety of the plan and also the executive responsible

for executing them works with a well defined interface.

Conclusion and Further Work

A mobile robotic plaform Barbora was introduced. The

platform is ready for deployment in our research facility.

Unfortunatelly the hardware proved to be more complicated than any of us

expected, leaving virtually no time to debug and tune the software in time to

compete at the Eurobot 2002 competition. However the competition has proved to

be an exceptional motivation while building the robot. Further work aticipates

polishing the software level and providing more experimental results about its

performace.

People

| Vojtěch Pavlík | mechanics, electronics, navigation, Linux kernel |

| Kamil Řezáč | mechanics, electronics, motor control |

| Zbyněk Winkler | strategy, high-level control |

| Martin Mareš | image processing, strategy, Linux kernel |

| Petr Daněček | image processing, object recognition |

| Jan Kára | path planning, RRT |

| Jaroslav Sládek | object tracking, finances |

| Markéta Kyloušková | French interpreter, moral support, T-shirts |

Funding

This project could not be realized without the funding and support of following people and organizations:

- Smrcek, American University of Guttenberg

- Faculty of Mathematics and Physics, Charles University in Prague

- Physics on Stage

- MGM Compro

- Loctite

- and all the team members that filled whatever there was missing

If you have found this project interesting or you have some comments

about it, please feel free to use our

feedback form.