Ball Manipulation

the quest for reliability and robustness

Ester's job is to collect small rugby balls at a 2x3m field. Last year's experience lead to the decision that reliability must be the main and most important property of any future manipulator. Dana's hand was nice and smart, but too delicate and Barbora's scroll feeder worked only sometimes and only with some balls. According to our observations the most reliable design for ball manipulation at Euroboot 2002 was the use of cylinders. Therefore cylinders are also the basis of our design.

First design |

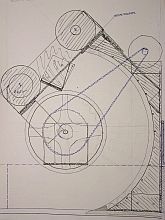

You can take a look at our first design at the picture. The mechanism

assumes that the balls are sufficiently compressable (and the motors in

the mechanism strong enough), so that it is possible to ignore the fact

that the balls are not spheres.

The mechanism works like this: the robot moves forward and

approaches the red ball. At this moment the brown cylinder is rotating

slowly, with constant velocity. The robot drives to the ball in a way

that the ball will be pushed between the cylinder and the floor first and

later then between the cylinder and the green metal sheet (the colors and

nomenclature taken from the schematic figure). Similar

to Barbora, but without the spiral. Then the brown cylinder is stopped

and the robot has to line up to the target. The ball is secured between

the cylinder and the green metal sheet and it is possible to drive through

the area. When it is lined up, the brown cylinder starts rotating again.

The ball is caught by the violet cylinder that rotates with a higher

velocity. That shoots the ball out. The violet cylinder's rotation

velocity determines the shape of the ballistic curve that the ball

follows.

You can see the first prototype made by

Pavel Jiroutek (Team Short Circuits Praha) on a video (you need the Xvid-codec

to play – download i.e. at http://koepi.roeder.goe.net/xvid.shtml).

Even prototype that simple worked astonishingly well. The cylinder only needs

a simple and small sprocket made out of Merkur (czech version of Meccano).

However it cannot shoot yet.

The prototype confirmed that a relatively strong motor is necessary to power

the main cylinder in order to overcome situations when the ball gets stuck

inside. The prototype uses a servo, modified for continuous rotation which,

alas, does not fulfill the requirements. Stronger motor is the so-called

brute-force appproach that usually works and is relatively easy to

implement but should be the last resort only when no “nicer”

solution can be found.

What alternatives are there to solve our problem? We will search for

an answer to this question until we better understand why this problem

arises and under what circumstances.

The ball can enter the shooting mechanism in an arbitrary orientation. As

long as it arrives “flatwise” everything is fine and it is transported further

without any problems. However when the ball enters oriented with the “tip

forwards” it could get stuck. The cylinder would try to rotate the ball further

into the direction where it is not round and than would not work out fine

.

There are to possible ways to deal with this:

- guarentee that the ball always arrives “flatwise”

- rotate the ball correctly inside, so that it cannot become stuck

The team Short Circuits Praha selected the first solution. Thanks to

the fact that the ball can be rolled in only one direction it is possible to

push the ball infront of the robot for a while. That lines up the ball in such a way

that it can freely roll into the direction of the robot movement. This is also

the optimal orientation for the ball to be sucked in by the cylinder.

We chose the second solution, because we hope that the shooting mechanism

will be more reliable and robust and finally also faster. Basic building blocks

are wooden beads. The big brown

cylinder from our previous design is adapted so that beads are spread out

across the whole surface. That allows pushing the ball to the side without

friction. The “green metal sheet” is also replaced with a construction made of

the beads. Further the construction is shaped in a way that the middle section

is further from the cylinder and the edges are closer.

Holes for the beads drilled into the cylinder are on a spiral and the wooden

beads are threaded on a copper wire that is wound up on the cylinder.

The whole construction can be seen on our drawing. The upper section

contains the shooting mechanism which consists of two independent

cylinders which provide the ball with the required energy. Their design is

based especially on the following data and computations:

A parabolic flight form is assumed, without air friction and the ball enters

the goal at the top of the curve (you can watch the mechanism on

a video).

|

|

Because the relation of ball and the cylinder energy is quadratic in relation

to the velocity with which the ball is let go, the energy ratio 1:10 stays fixed

even for higher velocities and it even gets better, because the

deformation energy is a constant. When brass is used, the energy ratio

is 1:30 (that is for shooting the ball into a distance of 2 m with an

angle of 10 degrees only 1/30 of the energy of the cylinder is

necessary).

The shooting mechanism can be watched on the video while shooting

forwards and upwards.

We get back to you with more information as soon as we finish the mechanism.

16.7.2004

We are sorry but due to the work on the robot we somehow did not manage to

complete this article earlier. The good news is though, that the suggested

mechanism worked (nearly) flawlessly during the competition.

You can see how the finished mechanism looked like when mounted onto

Ester on the picture. The front part (in front of the camera that is used to

search for the balls) contains an infrared barrier to detect the incoming

balls. Other sensors include the encoders (without the

possibility to detect the direction of the rotation) on each of the three

cylinders. The sensory equipment could be mentioned as one of the biggest

shortcomings. During the time we designed the whole mechanism, it was

not really clear what kind of sensors would be needed and so we implemented

something simple thinking that should that prove to be insufficient we will

improve it. But as the competition date came closer and closer we

had many things of greater urgency. Apart from that, even now

it is unclear how the optimal solution would look like.

When we shot the ball to the goal right after colection, everything was

fine. Problems arose in the moment when we decided to collect several

balls and shoot them altogether. The algorithm for one ball looked like

this: (a) turn on the cylinder (b) when the infrared barrier is

interrupted count N encoder ticks and stop the cylinder (c) report

a ball in the robot. The modification for two balls was quite

complicated. The actual algorithm was more or less the same, but the

problem lied in the detecton of the number of balls in the robot.

When searching for one ball, it didn't matter how

many balls the robot actually collected (1, 2 or 3?), but when searching

for more balls this information was “somewhat” crucial.

Apart from that the strategy to search for several balls proved to be an

almost complete failure. During the first two fights in France we did not score

even once, because Ester kept on searching for a second ball after it had

already collected the first and typically ran into the opponent in the meantime

which caused the loss of position tracking and defacto the end of all chances.

We returned to our strategy “collect-and-shoot” but due to profound

modifications of the code to support collecting several balls, the detection was

not reliable.

On the other hand it was really nice to watch the actual shooting. The

shooting cylinders were crancked up to the appropriate speed for the given

distance to the goal and all balls in the robot were shoved through it

gradually. Aside from temporary drop-outs of the encoders due to

loose contacts, noone could really complain. Ester shot without

bigger problems even over the diagonal and always hit the goal.

If you have questions or remarks – contact us. We will happily answer

you. Thanks for most of the fotos, videos and computations to Vojtěch

Pavlík.